Complexity of Pharma Logistics simplified by Digitization

Temperature control management or Refrigerated storage & transport otherwise known as Cold Chain are critical elements of any business dealing with temperature sensitive products. Knowing that the average refrigerated transport truck can have variations of up to 6⁰C, but that a great majority of medicine can become pharmacologically inactive with a 2⁰C difference is enough to emphasize, why cold chain matters. This sector continually spars with a high number of quality standards and increasing pressure of regulations. Especially in times of a pandemic the cold chain is facing the same challenges of global supply chains with the added concern of keeping the products from becoming pharmacologically inactive. With a large range of products and different stakeholders this can be a challenge to assure a closed cold chain. A high number of critical points or (product) handovers poses a risk to human safety and product integrity which can erode a business entirely. On the flip-side today’s economy and the industry are becoming more and more data-driven. These critical points provide an extensive opportunity for analytics in capturing data.

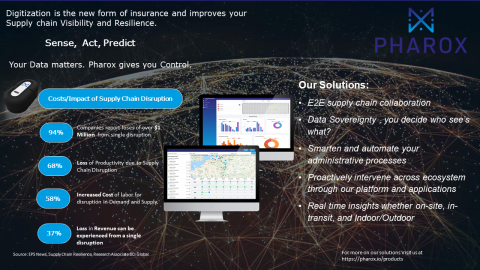

There have been tremendous improvements on infrastructure, technology, and ways of collaborating between partners in the last years, but the Covid-19 crisis has also distorted the balance between efficiency, flexibility, and resilience. The pressure of a limited shelf-life and high value characteristic of these value chains make them even more vulnerable to external influences. Being a decade’s long topic, a crisis response to product safety, constraints, and waste is now the driving force to pursue digital solutions for traceability, visibility, temperature monitoring and a seamless data infrastructure. Here at Pharox data matters, maintaining product integrity “from farm to fork or from trial to vial” remain crucial for Food and Pharma, which is why we offer End to End auditable trails.

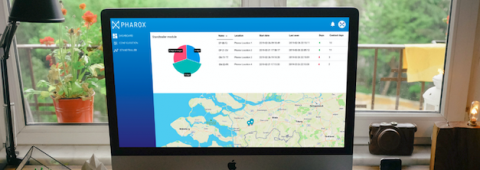

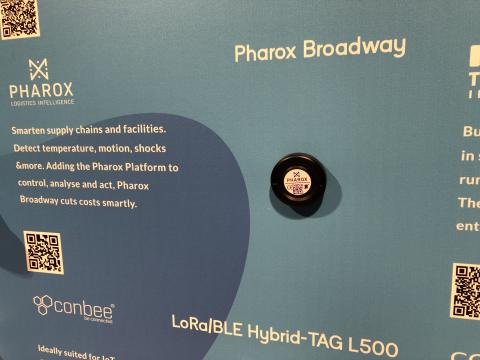

Do you have flexible sourcing? Can you absorb sudden demand peaks? How dynamically are your systems integrated with your supply chain partners? It’s all about data points, these are everywhere from raw data to meta data. To own up to being resilient you have to ensure each chain in your total supply chain is just as compliant. Pharox offers solutions which are industry independent. Our sophisticated IoT ecosystem, sensors, and apps capture real-time and historic data. The configurable aspect also puts you in control as to what information is notified and how it is shared, with who, when, where and why. The full auditable trail and real-time monitoring also facilitate claims. Stay alert on any non-conformities or deviation from your contracts. With our technology not only do you drive down costs, increase efficiency, and optimize & automate processes. You also assure human safety & product integrity whilst being immediately compliant to the stringiest regulations.

From regulations to single item compliance

In light of the growing complexity of regulations. The Pharma industry is projected to move to a fully transparent industry by 2023. Topics along this include the track & trace intensity of pharmaceuticals before circulation, in circulation and even years after having circulated in the market. These include full-unit level traceability. The Falsified Medicines Directive (2019) adds an extra regulative layer based on unique identifiers and anti-tampering devices. Pharox is not just a technological logistics intelligence company. Pharox is symbolic to years of expertise and knowledge in the logistics industry, we are very familiar with the pressure and needs the pharma industry faces which is why we treat them as our own when developing solutions. With the current trend towards industry granularity and Pharmaceutical serialization there is much talk about hierarchical relations for tracing container-batch-pallet and single items. Our sensors incorporate a full auditable trail for these hierarchical relations while at the same time providing the anti-tampering functionality. Through special sealing and our devices we are able to detect whether products have been tampered with. Think of open/close, tilt, shock, unauthorized handling, and a mechanism that ensures the shipments integrity is not compromised. The directive will also require verification at intermediate points which include aggregation and subtraction, another reason why data matters. Let Pharox be your ticket for being future proof in the Pharma industry.

“Download Cold Chain Brochure” or contact us directly at [email protected] for all your cold chain needs